April 2024

How to transform your manual logistics process into a fully automated one?

Warehouse managers who embrace the shift from manual operations to fully automated systems are taking a great step forward. With Lowpad, there’s no need to worry about the transition from manual to automated systems. We offer an effective, flexible automation solution that reduces concerns and provides guidance.

In today's fast-paced world, automation rapidly transforms most industries, offering benefits such as increased efficiency and productivity. While it's natural to have reservations about switching to automated systems, it's important to remember that the benefits outweigh the concerns. The technology's complexity, the team's reaction, and the operation's ability to handle such a significant transition are valid concerns. Still, they should encourage warehouse managers to integrate new technologies to tackle daily challenges. With proper planning and execution, automated systems can improve warehouse operations and lead to greater success.

Let's explore how Lowpad can help you make the transition as smooth as possible.

Seamless integration

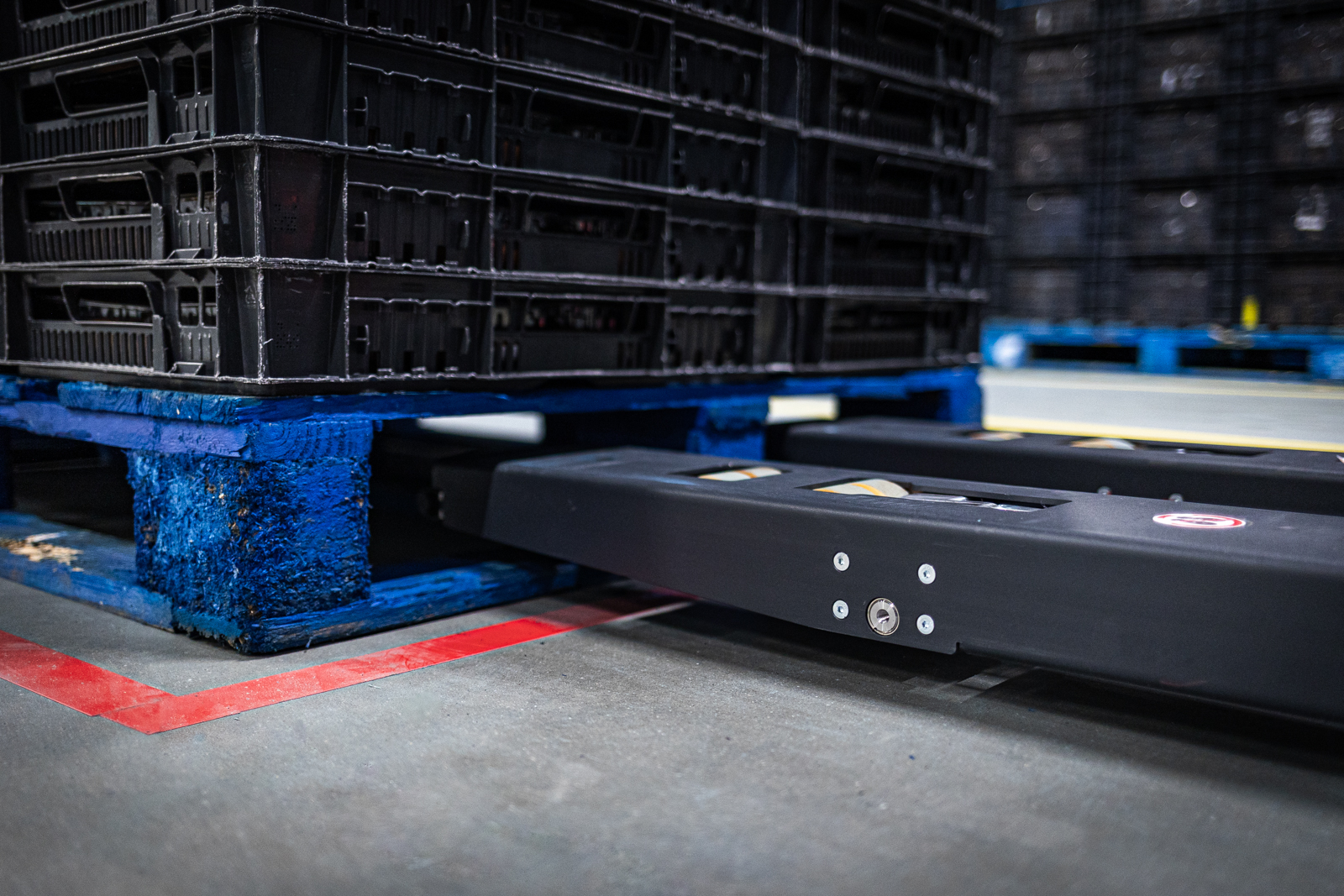

Warehouse managers are often wary of adopting robotics due to the potential disruption it may cause to operations. However, implementation is seamless with Lowpad AMRs. Our robots start optimizing your warehouse immediately without requiring extensive facility renovations. This means you no longer need to worry about any downtime or disruption to your operations.

Team collaboration

Are you worried that your team may not be comfortable working alongside robots? With Lowpad's Autonomous Mobile Robots (AMRs), there's no need to worry. Lowpads are designed to work alongside human workers, not replace them. By handling repetitive tasks such as transportation and moving, Lowpads help your team focus on more important and fulfilling work. The result? Increased productivity and happier employees who see robots as helpful teammates rather than a threat to their jobs.

Real-time analytics

Efficient and optimized warehouse operations are crucial for any business to succeed. Lowpad provides an advanced solution that consists of state-of-the-art Autonomous Mobile Robots (AMRs) paired with intuitive software. This solution enables you to have better control of your workflows and get real-time insights into your operations. Our software solution offers rich dashboards with real-time analytics on key metrics such as inventory management and task execution. By integrating with your existing systems, Lowpad allows seamless data interchange, making it easier for you to optimize workflows and make informed decisions.

Scalable solution

Lowpad provides a flexible solution that enables businesses to manage their investments in line with their demand. This flexibility gives clients the ability to implement high levels of automation without making huge upfront investments, ensuring operational efficiency is balanced with their needs. With Lowpad, you can always meet demand without having to over-invest in fixed assets.

Reshaping intralogistics

Transitioning to automated warehouse operations may seem overwhelming. However, with Lowpad's innovative automation solutions, you can confidently move forward into the future. Lowpads are specifically designed to improve your workflows, not to cause disruption. We reshape your intralogistics processes by providing your team with the necessary tools to thrive.

Read other

news

Back to overview

February 2026

Customer story GXO - Inbound

With the Lowpad F, GXO is taking the inbound process to the next level. Pallets move safely, efficiently, and autonomously from dock to storage, while employees are relieved of repetitive tasks and room is created for further growth.

Read more

August 2025

Lowpad is coming to the UK!

This September, we’re bringing our Lowpad F, designed for pallet transport, and Lowpad S, ideal for roll cage handling, to the UK for free, on-site demos right at your facility.

Read more