Roll cages and dollies

Lowpad S

Floor-to-floor transportation

The Lowpad S fits underneath all existing roll cages.

Insights

Real-time data for optimization and decision-making.

Omnidirectional driving

Small turning radius for narrow pathways.

We take care of all your roll cages

The Lowpad S is the automation solution for companies handling food distribution, post, and parcel services. Our robust and safe AMRs are designed to transport roll cages and rollies without hassle. With our Lowpads, you can boost your performance to the next level by gaining real-time insights, accuracy, and better utilization of scarce human resources.

Suitable for the job

The Lowpad S is a versatile autonomous mobile robot that can automate various logistical processes, seamlessly handling standard roll cages. Experience improved productivity and reduced operational costs in your intralogistics with our advanced automation solution tailored to your requirements. Our experts will collaborate with you to deliver a high-quality, tailored system that streamlines workflows, reduces downtime, and maximises efficiency. Our solution is designed to streamline your processes, reduce downtime, and increase efficiency. Don't hesitate to contact us today to learn how the Lowpad S can transform your operations and drive measurable benefits for your organisation.

Technical

Specifications

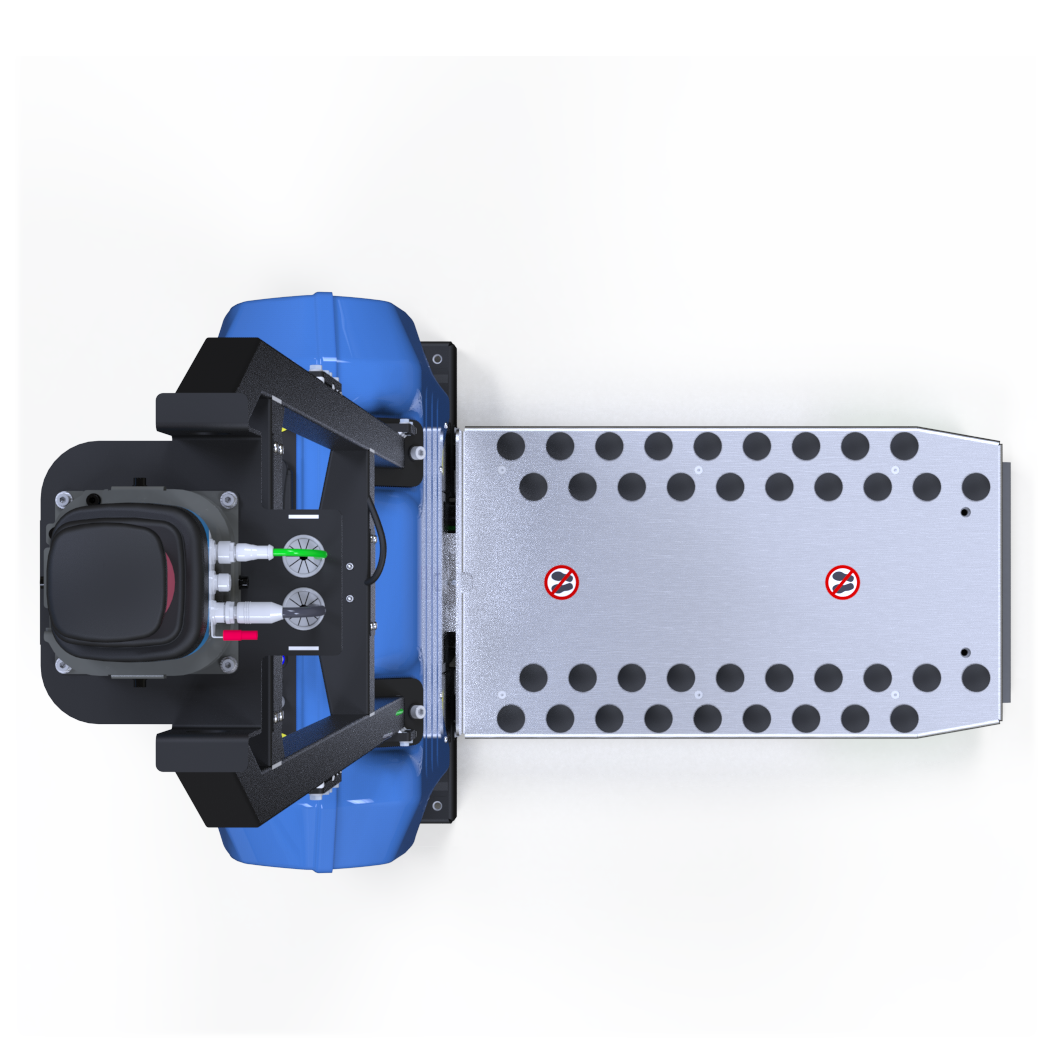

Sizing and capacity

Dimensions

1150 x 700 x 2235 mm

45.3" x 27.6" x 88.0"

Dimensions Lifting table

760 x 446 x 116 mm

29.9” x 17.6” x 4.6”

Lifting Capacity

450 kg

992 lbs

Lifting height

200 mm

7.9”

Speedrange

1.2 m/s

Loads

Suitable loads

Roll cages

Carts

Applications

Moving

Marshalling

Inbound

Cross Docking

A to B transport

Picking

Dynamic Zone Picking

Customer success stories

transition today

Let’s discuss the best automation solution for you!