Danish CC trolleys and Pick carts

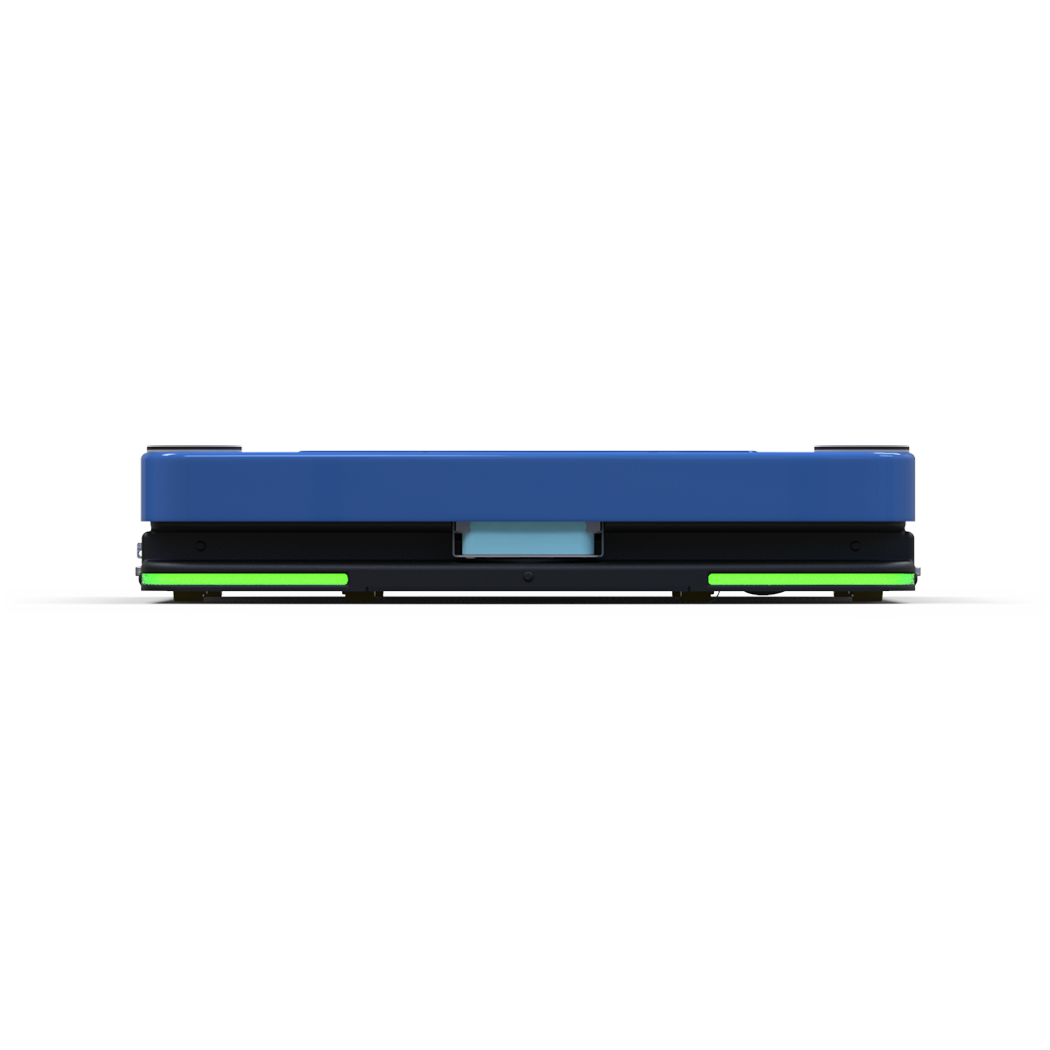

Lowpad M

Lowest available AMR

The lowest AMR available on the market, with a height of only 128 mm.

Insights

Real-time data for optimization and decision-making.

Collaborative robot

Endless possibilities for human-robot interaction within shared spaces.

The lowest available AMR

The Lowpad M is a highly advanced mobile robot designed to cater to the needs of pick carts and Danish CC trolleys. Its ultralow height of only 128 mm makes it the perfect solution for load carriers with a minimum height between the cart and the floor.

One of the most significant advantages of the Lowpad M is that it ensures the gentle and safe transport of goods, which is essential in any logistics process. This is due to its unique characteristics, which make it versatile to automate various logistical processes. By integrating this type of automation, you can improve your productivity while lowering your operating costs in your intralogistics.

Suitable for the job

The Lowpad M is the ultimate solution for the autonomous movement of pick carts and Danish CC trolleys. Its ability to carry heavy loads (up to 450KG) ensures improved ergonomics on your work floor, making it a valuable addition to any logistics process. Additionally, Lowpads are built to withstand all environments, providing a robust backbone for your entire logistic process.

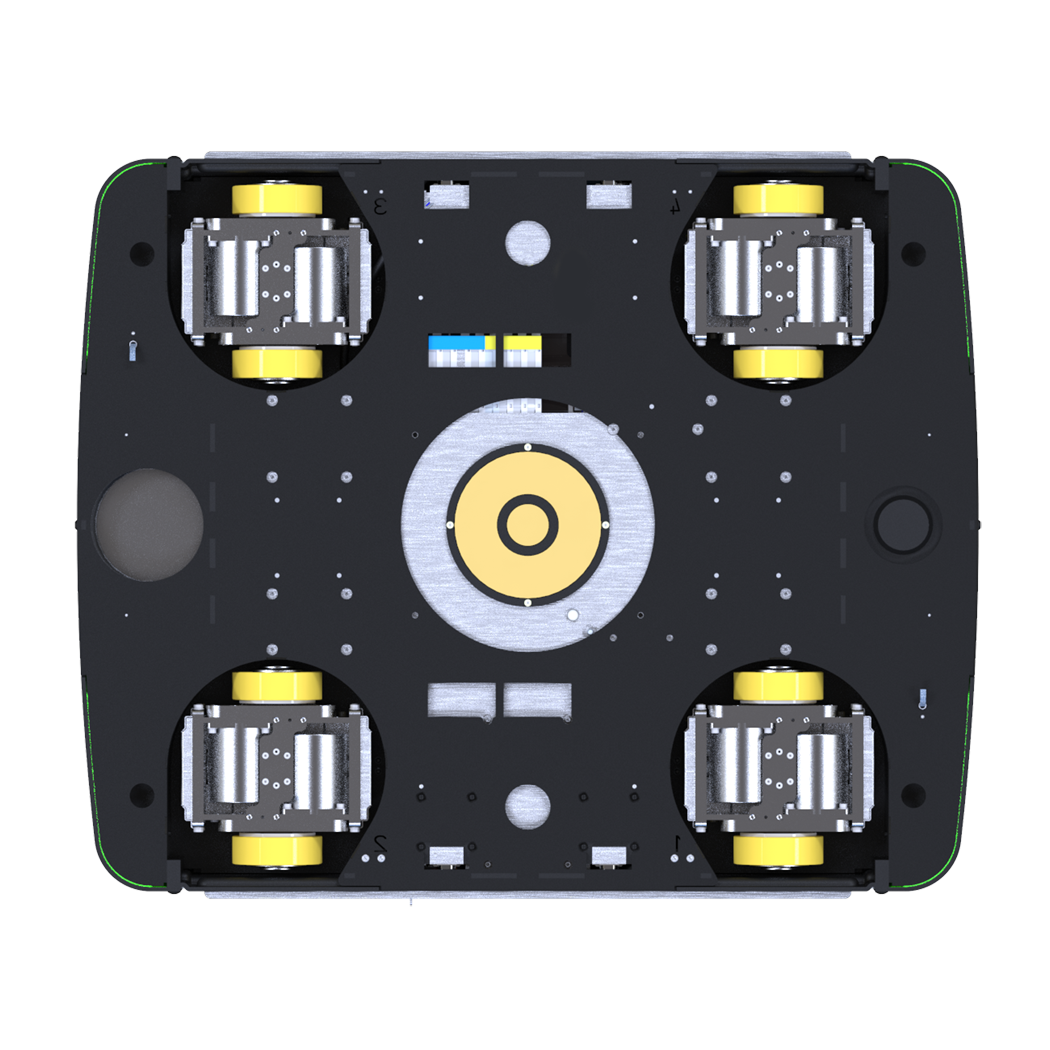

Technical

Specifications

Sizing and capacity

Dimensions

665 x 800 x 125 mm

26.2” x 31.5” x 5”

Lifting Capacity

450 kg

992 lbs

Lifting height

40 mm

1.57”

Speedrange

1.2 m/s

Loads

Suitable loads

Danish CC Trolleys

Pick carts

Applications

Moving

Marshalling

Inbound

Cross Docking

A to B transport

Picking

Dynamic Zone Picking

Customer success stories

transition today

Let’s discuss the best automation solution for you!